YUANYI CNC

LATHE CENTER

Knife CNC lathe

- TCK5240 hard rail tailstock CNC lathe

- CK52X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK52X/D turret ramp precision CNC lathe (without tail)

- CK46X/D turret ramp precision CNC lathe (without tail)

Knife tower turning milling composite CNC lathe

- CK52Z/DYA power turret turning milling composite precision CNC lathe

- CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

- CK46Z/DYA power turret turning milling composite precision CNC lathe

- CK46X/DMY power turret Y-axis turning and milling composite CNC lathe

- CK46X/XDYA turret turning and milling composite precision CNC lathe

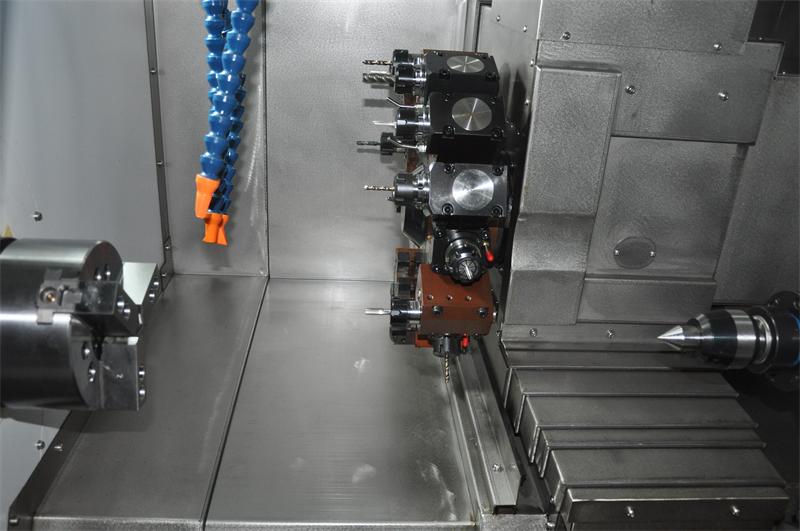

CK46X/DMY power turret Y-axis turning and milling composite CNC lathe

- Product details

|

|

Main Technical Parameters |

||

|

|

|||

|

|

Machining range |

Maximum rotary diameter |

450mm |

|

|

Maximum machining diameter of disk |

350mm |

|

|

|

Maximum turning length |

420mm |

|

|

|

Maximum milling length |

450mm |

|

|

|

Maximum bar diameter |

Ø45mm |

|

|

|

Minimum distance from jaws to cutterhead |

-50mm |

|

|

|

Maximum distance from chuck jaws to cutterhead |

450mm |

|

|

|

Spindle |

Spindle nose type |

A2-5 |

|

|

Spindle through hole |

Ø56mm |

|

|

|

Maximum spindle speed |

0-5000r/min |

|

|

|

Spindle pulley tooth shape |

8YU |

|

|

|

Tail top |

Tip type |

Mo type 4 |

|

|

Sleeve diameter |

Ø95mm |

|

|

|

Cylinder working pressure |

5-20KG |

|

|

|

Tailstock stroke |

400mm |

|

|

|

Tailstock structure |

Flat-mounted sliding hard rail |

|

|

|

Stroke of center |

100mm |

|

|

|

Maximum distance from jaws to center |

430mm |

|

|

|

Feed |

X-axis guide type |

30 roller p |

|

|

Z-axis guideway type |

35 roller p |

|

|

|

X-axis screw type |

3210-C3 |

|

|

|

Z-axis screw model |

3210-C3 |

|

|

|

Screw bearing |

2562-P4 |

|

|

|

Stroke |

Maximum X-axis travel |

250mm |

|

|

Maximum travel of Z-axis |

510mm |

|

|

|

Maximum Y-axis travel |

Maximum travel of Y-axis 35mm |

|

|

|

Rapid traverse speed |

X-axis rapid positioning |

≤18m/min |

|

|

Z-axis rapid positioning |

≤18m/min |

|

|

|

Accuracy |

X-axis repetitive positioning |

0.003mm |

|

|

Z-axis repetitive positioning |

0.003mm |

|

|

|

Machine structure and protection |

Structure of the machine |

30 degree integral casting |

|

|

Protection |

Fully enclosed |

|

|

|

Dimension |

Dimension(L*W*H) |

2730mm*1710mm*1920mm |

|

|

Weight (L*W*H) |

3550kg |

|

|

|

|

||||||

|

|

|||||||

|

|

Spindle motor |

Taiwan New Generation 7.5KW |

|||||

|

|

Spindle |

A2-5 sleeve spindle KENTURN / HAOZHI |

|||||

|

|

Numerical control system |

Taiwan Xindai 22TB |

|||||

|

|

X, Z, Y, A-axis servo motor |

Taiwan Shindai 2.4KW |

|||||

|

|

X, Z, Y-axis screws |

Taiwan Yintai |

|||||

|

|

X-axis guide rail |

Taiwan Yintai |

|||||

|

|

Z-axis guide rail |

Taiwan Yintai |

|||||

|

|

X-axis, Z-axis support screw bearings |

Germany FAG |

|||||

|

|

Lubrication assembly |

River Valley |

|||||

|

|

Hydraulic assembly |

Taiwan Quanmao |

|||||

|

|

Turret |

BMT40 One-piece straight Y15 station power servo turret |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

1. This machine adopts 30° integral slant bed structure with hydraulic tailstock ejector pin and Y-axis 12-position power turret. It can be used for turning and milling composite machining for disc and shaft.

Second, the machine tool servo spindle adopts the encoder double feedback structure, which can realize high-precision indexing and linkage function, which can complete side milling, drilling and tapping at one time; face milling, drilling, tapping, curve milling Such precision machining, effectively improving product accuracy and production efficiency, saving investment in secondary processing equipment, is a very high-cost turning and milling composite CNC lathe.

Third, the main shaft adopts the sleeve main shaft with the standard inner cone structure, the hydraulic chuck and the spring collet can be directly installed. Without the transition flange, the chuck can be quickly replaced.

4. The spindle adopts maintenance-free structure and uses precise high-speed angular contact bearings. The maximum speed can reach 6000 rpm, which can effectively perform high-speed cutting and improve the surface roughness of the machined workpiece.

5. The machine tool adopts imported precision high-speed silent screw and uses the unique pre-tensioning fixed structure to effectively improve the rigidity of the machine tool and eliminate the precision change caused by the cold and heat changes caused by the machine operation.

Sixth, the x-axis guide rail adopts German linear guide rail, which has the advantages of good rigidity, high precision, long service life and easy maintenance.

7. The screw guide rail adopts liquid automatic lubrication method to effectively protect important parts and prolong their service life.

Eight, the use of imported control system, and with the Japanese Yaskawa ultra-precision servo (24-bit encoder), the machine processing accuracy and processing speed has been effectively improved.

9. This machine tool is suitable for the processing of precision parts such as aviation equipment, optoelectronics, automobile, sanitary ware and lighting.

Tips: Machine technology continues to improve, the company has the final interpretation of all technical parameters.

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/X precision ramp milling and milling CNC lathe

CK46X/X precision ramp milling and milling CNC lathe

CK36X row knife ramp precision CNC lathe

CK36X row knife ramp precision CNC lathe