YUANYI CNC

LATHE CENTER

Knife CNC lathe

- TCK5240 hard rail tailstock CNC lathe

- CK52X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK52X/D turret ramp precision CNC lathe (without tail)

- CK46X/D turret ramp precision CNC lathe (without tail)

Knife tower turning milling composite CNC lathe

- CK52Z/DYA power turret turning milling composite precision CNC lathe

- CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

- CK46Z/DYA power turret turning milling composite precision CNC lathe

- CK46X/DMY power turret Y-axis turning and milling composite CNC lathe

- CK46X/XDYA turret turning and milling composite precision CNC lathe

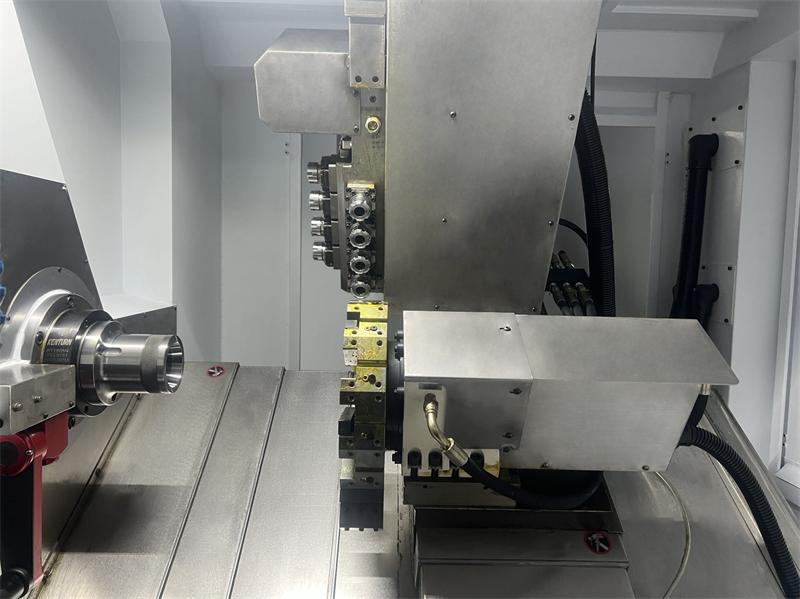

CK46X/XDYA turret turning and milling composite precision CNC lathe

- Product details

|

Main technical parameters: |

||

|

Processing range |

Maximum swing diameter of the machine |

¢250mm |

|

Maximum bar diameter to be processed |

¢45mm |

|

|

Maximum processing length |

150mm |

|

|

Maximum clamping diameter |

¢160mm |

|

|

spindle |

Spindle nose form |

A2-5 |

|

Spindle through-hole |

¢56mm |

|

|

Maximum spindle speed |

0-5000r/min |

|

|

Spindle pulley tooth shape |

8M/8YU |

|

|

Power head |

Power head structure |

cogs |

|

Power head specifications |

ER20 |

|

|

Number of power heads |

4+4 power head 1 group |

|

|

Feed |

X-axis guide model |

35 Balls P |

|

Z-axis guide model |

35 Balls P |

|

|

X-axis screw model |

3210-C3 |

|

|

Z-axis screw model |

3210-C3 |

|

|

Screw bearings |

2562-P4 |

|

|

itinerary |

X-axis maximum travel |

800mm |

|

Maximum travel in the Z-axis |

250mm |

|

|

Maximum travel of the Y-axis |

150mm |

|

|

Rapid traverse speed |

X-axis fast positioning |

≦28m/min |

|

Z-axis fast positioning |

≦28m/min |

|

|

precision |

X-axis repetitive positioning |

Soil 0.005mm |

|

Repeat positioning in the Z-axis |

Soil 0.005mm |

|

|

Machine tool structure and protection |

structure |

30 degree integral casting |

|

Protection mode |

Semi-enclosed |

|

|

Dimensions |

Dimensions (L*W*H). |

2450mm*1750mm*2050mm |

|

weight |

2950kg |

|

|

Main configuration |

||||||

|

Spindle motor |

Taiwan's new generation 7.5KW |

|||||

|

spindle |

A2-5 SOCKET SPINDLE KENTURN/HAOZHI |

|||||

|

Numerical control system |

Taiwan's new generation 22TB |

|||||

|

X, Z, Y axis servo motors |

Taiwan's new generation 2.4KW |

|||||

|

X-axis, Z-axis screw |

Taiwan Shangyin 3212-C3 grade |

|||||

|

X-axis, Z-axis guides |

Taiwan Bank P grade |

|||||

|

X-axis and Z-axis support screw bearings |

German FAGP42562 |

|||||

|

Automatic lubrication system |

river valley |

|||||

|

Hydraulic assembly |

Taiwan Quanmao |

|||||

|

Dota |

12-station servo turret |

|||||

|

Power head |

1 group of 4+4 power heads (4 side mills, 4 end mills) |

|||||

|

(The company reserves the right to change specifications without prior notice) |

||||||

1.the machine adopts 30° integral slant bed structure, novel structure, power head and Y-axis adopt heavy cutting structure, precision grinding gear, low noise, high speed and long service life, with eight-station hydraulic service turret , the perfect realization of the turning and milling composite function.

2.the servo spindle of this machine adopts double feedback encoder, the indexing precision can reach 0.001 degree, which can effectively improve the positioning accuracy of turning and milling, and cooperate with 4+4 gear type power head, Y axis and eight station servo turret. It can perform high-precision and complex parts processing, such as side, face milling, drilling, tapping, face milling and other interpolation processing, improve product positioning and machining accuracy, save investment in secondary processing equipment, is a cost-effective Very ideal for turning and milling composite CNC lathes.

3. The main shaft adopts the sleeve main shaft with standard inner cone structure, hydraulic chuck and spring collet. It can be directly installed without the need of transition flange. It can quickly change the chuck and external hydraulic brake, so the milling process is not Vibration, effectively improve the roughness of the workpiece.

4. The spindle adopts maintenance-free structure and uses precise high-speed angular contact bearings. The maximum speed can reach 6000 rpm, which can effectively perform high-speed cutting and improve the surface roughness of the machined workpiece.

5. The machine tool adopts imported precision high-speed silent screw and uses the unique pre-tensioning fixed structure to effectively improve the rigidity of the machine tool and eliminate the precision change caused by the cold and heat changes caused by the machine operation.

Sixth, the x-axis guide rail adopts German linear guide rail, which has the advantages of good rigidity, high precision, long service life and easy maintenance.

7. The screw guide rail adopts liquid automatic lubrication method to effectively protect important parts and prolong their service life.

8.the use of imported control system, and with the Japanese Yaskawa ultra-precision servo (24-bit encoder), the machine processing accuracy and processing speed has been effectively improved.

9. This machine tool is suitable for the processing of precision parts such as aviation equipment, optoelectronics, automobile, sanitary ware and military.

Tips: Machine technology continues to improve, the company has the final interpretation of all technical parameters.

- Last:There is no content!

- Next:CK46X/DMY power turret Y-axis turning and milling composite CNC lathe

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/X precision ramp milling and milling CNC lathe

CK46X/X precision ramp milling and milling CNC lathe

CK36X row knife ramp precision CNC lathe

CK36X row knife ramp precision CNC lathe