YUANYI CNC

LATHE CENTER

Knife CNC lathe

- TCK5240 hard rail tailstock CNC lathe

- CK52X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK52X/D turret ramp precision CNC lathe (without tail)

- CK46X/D turret ramp precision CNC lathe (without tail)

Knife tower turning milling composite CNC lathe

- CK52Z/DYA power turret turning milling composite precision CNC lathe

- CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

- CK46Z/DYA power turret turning milling composite precision CNC lathe

- CK46X/DMY power turret Y-axis turning and milling composite CNC lathe

- CK46X/XDYA turret turning and milling composite precision CNC lathe

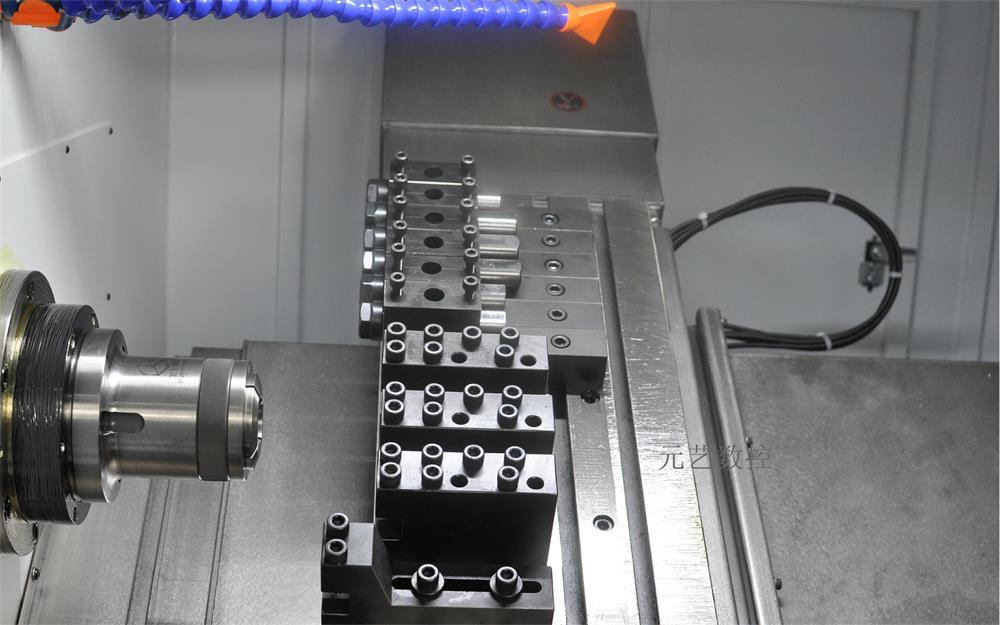

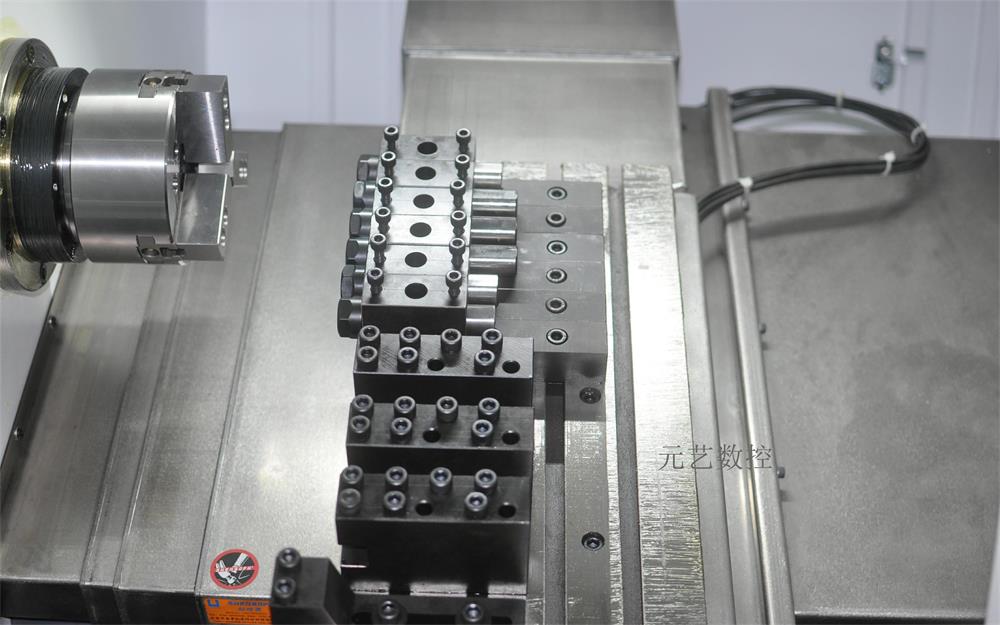

CK46X row knife ramp precision CNC lathe

- Product details

1. This machine adopts 30° integral inclined bed structure, which is easy to remove chips, low center of gravity, strong bending resistance, good protection of parts and easy to operate.

2. The arrangement of tools is adopted to effectively avoid the accuracy error caused by tool change, and improve the speed of tool change and save processing time.

3. The spindle adopts a sleeve spindle with a standard inner cone structure, a hydraulic chuck, and a spring chuck can be installed directly, without a transition flange, and the chuck can be quickly replaced.

Fourth, the spindle adopts a maintenance-free structure, and uses a precision high-speed angular contact bearing, the maximum speed can reach 6000rpm, which can effectively carry out high-speed cutting and improve the surface roughness of the workpiece.

Fifth, the machine tool adopts imported precision high-speed silent screw rod, and adopts double pre-tension fixed structure, so that the rigidity of the machine tool can be effectively improved, and the accuracy change caused by the cold and hot deformation caused by the operation of the machine tool is eliminated.

6. The two-axis guide rail adopts the linear guide rail imported from Germany, which has the advantages of good rigidity, high precision, long life and easy maintenance.

7. The screw guide rail adopts liquid automatic lubrication method, which effectively protects important components and prolongs its service life.

8. The imported control system is adopted, and the high-speed ultra-precision servo (24-bit encoder) of Japan Yaskawa is used to effectively improve the machining accuracy and processing speed of the machine tool.

9. This machine tool is suitable for the processing of precision parts such as aviation equipment, optoelectronics, automobiles, sanitary ware, and military industry.

Tips: Machine technology continues to improve, the company has the final interpretation of all technical parameters.

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/X precision ramp milling and milling CNC lathe

CK46X/X precision ramp milling and milling CNC lathe

CK36X row knife ramp precision CNC lathe

CK36X row knife ramp precision CNC lathe