YUANYI CNC

LATHE CENTER

Knife CNC lathe

- TCK5240 hard rail tailstock CNC lathe

- CK52X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

- CK52X/D turret ramp precision CNC lathe (without tail)

- CK46X/D turret ramp precision CNC lathe (without tail)

Knife tower turning milling composite CNC lathe

- CK52Z/DYA power turret turning milling composite precision CNC lathe

- CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

- CK46Z/DYA power turret turning milling composite precision CNC lathe

- CK46X/DMY power turret Y-axis turning and milling composite CNC lathe

- CK46X/XDYA turret turning and milling composite precision CNC lathe

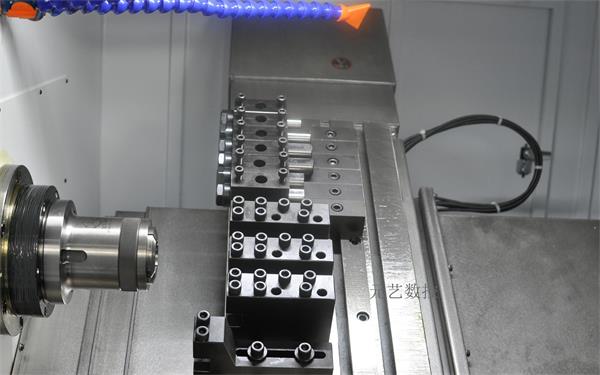

CK36X row knife ramp precision CNC lathe

- Product details

Lathe specifications

CK36X precision inclined rail CNC lathe

1

Machine structure

Inclined bed

2

Knife form

Platoon knives

3

Number of knives

8-12 pieces (show the diameter of the workpiece)

4

Tool specifications

16mm、20mm

5

Spindle specifications

A2-4

6

Spindle structure

Sleeve type

7

Spindle bore diameter

¢46mm

8

Spindle motor power

4KW servo

9

Maximum spindle speed

6000rpm

10

The slide plate is high to the center of the spindle

50mm

11

Workpiece clamping method

Hydraulic

12

Chuck specifications

5 inch hydraulic chuck

13

Maximum clamping diameter

¢125mm

14

Maximum swing diameter of the machine

¢250mm

15

Maximum bar diameter to be processed

¢35mm

16

Maximum processing length

150mm

17

X-axis travel

790mm

18

Z-axis travel

200mm

19

Rapid movement speed in the X and Z axes

36m/min

20

Repeatability accuracy

0.003mm

21

Machining accuracy

±0.005mm

22

Feed motor power

0.85KW

23

Hydraulic assembly motor power

1.2KW

24

Feeding method

Oil bath type

25

Lubrication method

automatic

26

Total power supply

6.5KW

27

Exterior dimensions

1850*1550*1600mm(L*W*H)

28

Machine weight

2500KG

|

1 |

Control system |

Taiwan's new generation |

|

2 |

Feed servo |

Japanese Yaskawa or new generation |

|

3 |

Precision ball screws |

Taiwan Yintai and Taiwan Bank of Shanghai |

|

4 |

Precision guide rails |

Taiwan's Bank of Shanghai, Germany's INA |

|

5 |

spindle |

Taiwan Pusen, Taiwan Luo Yi ROYAL, Haozhi DKDAKE |

|

6 |

Spindle drive |

Beijing super synchronous servo |

2、 Adopting a cutting structure effectively avoids precision errors caused by tool changes, and improves tool change speed, saving processing time.

3、 The spindle adopts a sleeve spindle with a standard inner cone structure, hydraulic chuck, and spring chuck, which can be directly installed without the need for transition flanges and can be quickly replaced with chuck.

4、 The spindle adopts a maintenance free structure and uses precision high-speed angular contact bearings, with a speed of up to 6000rpm, which can effectively perform high-speed cutting and improve the surface roughness of the workpiece.

5、 The machine tool adopts imported precision high-speed silent screw and adopts a double pre tensioning fixed structure, which effectively improves the rigidity of the machine tool and eliminates the accuracy changes caused by cold and hot deformation caused by the operation of the machine tool.

6、 The two axis guide rail adopts linear guide rails imported from Taiwan and Germany, which have the advantages of good rigidity, high precision, long service life, and easy maintenance.

7、 The screw guide rail adopts liquid automatic lubrication method, effectively protecting important components and extending their service life.

8、 By adopting an imported control system and cooperating with the Yaskawa high-speed ultra precision servo (24 bit encoder) from Japan, the machining accuracy and speed of the machine tool have been effectively improved.

9、 This machine tool is suitable for precision parts processing in aviation equipment, optoelectronics, automotive, bathroom, military and other industries.

Tips: Machine technology continues to improve, the company has the final interpretation of all technical parameters.

- Last:There is no content!

- Next:CK46X row knife ramp precision CNC lathe

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK52X/DMY power turret turning milling composite CNC lathe (tailstock, straight Y-axis)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/DM turret inclined rail tailstock precision CNC lathe (with hydraulic thimble)

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/XY row cutter Y-axis turning and milling composite precision CNC lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/S Multi-Cutting Turning and Milling Compound Precision CNC Lathe

CK46X/X precision ramp milling and milling CNC lathe

CK46X/X precision ramp milling and milling CNC lathe